A new study from the University of Southampton has demonstrated a new method to safely clean and reuse facemask respirators with advanced low-temperature plasma technology. The discovery could help future pandemic responses by providing contingency options should a shortage of personal protective equipment (PPE) for frontline healthcare staff occur again.

The study, published in the journal AIP Advances showed that the technology can remove 99.99% of coronavirus from contaminated facemasks while maintaining their ability to filter out harmful airborne droplets.

The results also showed that this technique could reduce approximately 70% of plastic waste caused by facemasks and reduce economic burdens on low-income countries by reusing facemasks.

Dr. Min Kwan Kim, Lecturer in Astronautics at the University of Southampton who led the research said, “The COVID-19 pandemic caused high demand for facemasks which led to global challenges in sustaining the supply chain. Because they are essential personal protective equipment to protect frontline healthcare against COVID-19, the chronic, global shortage of N95 and N99 facemasks is one of the most urgent threats to our collective ability to save lives from the coronavirus.

“Although most of the masks are considered one-time use, the reuse of masks may need to be considered as a crisis capacity strategy to ensure continued availability for COVID-19 and future pandemics,” he continued.

Whilst other techniques to decontaminate PPE have been trialed, including hydrogen peroxide, ultraviolet irradiation, and moist heat, these can negatively affect the masks performance in future use, either by damaging the filters or leaving residues that are harmful to skin.

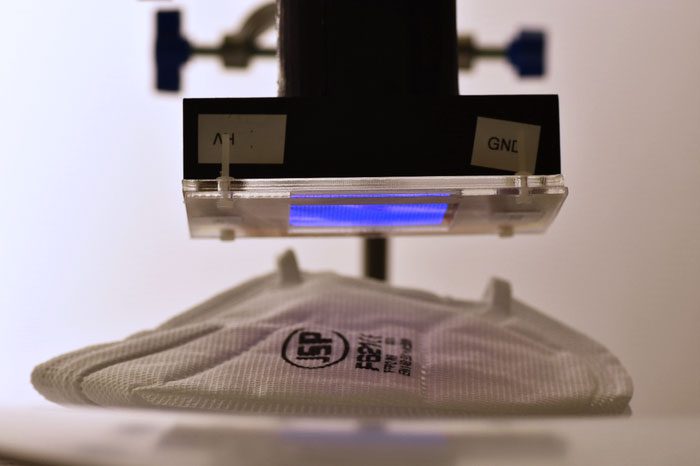

In this latest study, the research team applied microdroplets containing SARS-CoV-2, the virus that causes COVID-19, to sample FFP2 and FFP3 facemasks, the most common masks used by frontline healthcare staff. A prototype decontamination system was then used to apply cold plasma to the samples for two, five and ten minutes. They then tested the samples for the presence of residual SARS-CoV-2 and transmitted aerosols of sodium chloride through the samples to monitor filter performance.

The results showed that the samples that were treated for ten minutes had been successfully decontaminated and the researchers found no significant impact on the filters for both the FFP2 and FFP3 masks.

In addition to offering a contingency strategy for health systems in the event of future rises in hospital admissions, there could also be significant benefits to the environment.

“Environmentalists warn single-use masks are adding to the glut of plastic pollution threatening the health of oceans and marine life. It has been estimated 129 billion single-use face masks are used monthly around the world, with 55 million a day in the UK,” noted Kim. “As the most of used face masks are incinerated or sent to landfills, their continued use on this scale can affect the UK’s ambitions to achieve net zero and reduce plastic waste.”

Development of a rapid plasma decontamination system for decontamination and reuse of filtering facepiece respirators. AIP Advances, 7 October 2021.