Detecting tuberculosis, malaria and other deadly infectious diseases as early as possible helps to prevent their rapid spread and allows for more effective treatments. But current detection methods are cost-prohibitive in most areas of the world. Now a new nanotechnology method—employing common, everyday shrink wrap—may make highly sensitive, extremely low-cost diagnosis of infectious disease agents possible.

The new technique, described in a paper published this week in The Optical Society’s (OSA) journal Optical Materials Express, offers a way to significantly boost the signal of fluorescent markers used in biosensing, by depositing a combination of metals onto shrink wrap.

“Using commodity shrink wrap and bulk manufacturing processes, we can make low-cost nanostructures to enable fluorescence enhancements greater than a thousand-fold, allowing for significantly lower limits of detection,” said co-author Michelle Khine, a biomedical engineering professor at the University of California, Irvine (UC Irvine). “If you have a solution with very few molecules that you are trying to detect—as in the case of infectious diseases—this platform will help amplify the signal so that a single molecule can be detected.”

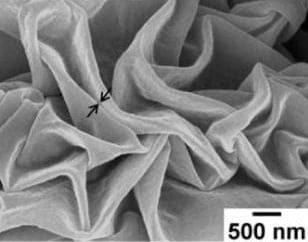

In the new method — developed by Khine and her graduate student Himanshu Sharma, along with their collaborators, Professors Enrico Gratton and Michelle Digman, also at UC Irvine — thin layers of gold and nickel are first deposited onto a thermoplastic polymer (a shrink wrap film). When heated, the shrink wrap contracts, causing the stiffer metal layers to buckle and wrinkle into beautiful flower-like structures that are significantly smaller than previously demonstrated. To the top of the wrinkled metal layer, the researchers add samples of biomarkers, antibodies generated by the immune system in response to infection with a certain pathogen. These biomarkers are tagged with fluorescent probes to allow their detection under near-infrared light.

The team found that the shrink wrap’s wrinkles significantly enhanced the intensity of the signals emitted by the biomarkers. The enhanced emission, Khine says, is due to the excitation of localized surface plasmons—coherent oscillations of the free electrons in the metal. When researchers shined a light on their wrinkled creation, the electromagnetic field was amplified within the nanoscale gaps between the shrink wrap’s folds, Khine said. This produced “hotspots”—areas characterized by sudden bursts of intense fluorescence signals from the biomarkers.

In their study, the researchers used an immune system molecule known as immunoglobin G, or IgG, as the biomarker. “IgG is one of the most common circulating antibodies in the immune system, making up about 80 percent of the all antibodies in the body, and is found in most bodily fluids,” Sharma said. In particular, IgG is a good biomarker for the detection of rotavirus, the virus that is the leading cause of severe diarrheal infection in infants and young children worldwide. IgG is also a biomarker for infection with the Epstein-Barr virus and Herpes simplex virus.

In the future, he says, additional antibodies, such as immunoglobulin A (IgA) and immunoglobulin M (IgM), might be used to detect other agents including cytomegalovirus and the pathogen that causes typhoid fever.

“The technique should work with measuring fluorescent markers in biological samples, but we have not yet tested bodily fluids,” said Khine, who cautions that the technique is far from ready for clinical use. For example, she notes, “We are currently working on trying to detect rotavirus, but one of the main challenges is that our surface is hydrophobic”—that is, water-repelling—”so diffusion of the biomarker onto our composite structures is limited.”

Though their current setup requires the use of expensive equipment, the researchers say, they believe their work will pave the way to creating an integrated, low-cost device to trap and identify biomarkers.

Read the study at Optical Materials Express: Enhanced Emission of Fluorophores on Shrink-Induced Wrinkled Composite Structures.